Citrus

Dried Peel / Powder

CITRUS PLANT

Orange processing facility has state of the art machinery imported from JBT food tech Italy & USA, Bucher Unipektin Switzerland and ALFA LAVAL Tumba - Sweden.

Patanjali has put unique machinery for evaporation i.e. TASTE ( Thermally accelerated short time evaporation ) machine which converts juice into concentration in few minutes and hence product is less abusive to Heat and which intern protect the Natural taste in Juice.

Plant installed unique machinery like DE-acidification plant to reduce acidity and DE-bittering plant to reduce Limonene.

Plant has facility to store 2000 MT Finished goods Deep-freezer Capacity (-18 to -20 Degree Centigrade).

Plant has online facility (2500 kg/hr. x 3 lines) to Dry and produce powder from Citrus Fruits peel/ pomace which is used in cosmetic industry. This is first of its kind plant in India.

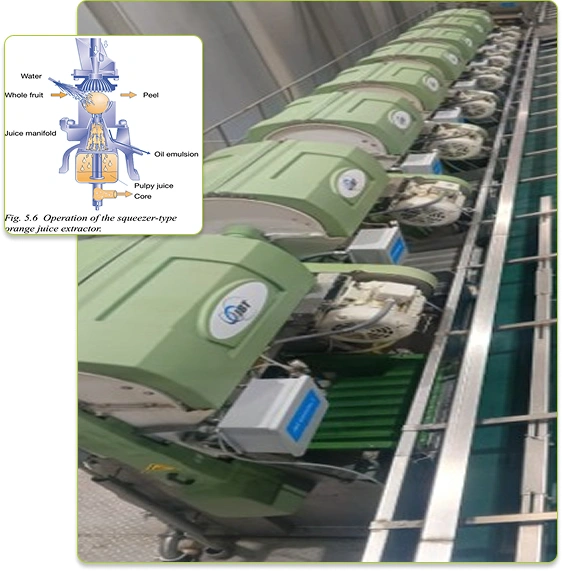

EXTRACTORS

Squeezer type extractors are place in a row in extractor room. Each extractor is fitted with 5 heads which are available in different sizes so that they can handle different types of available fruits. The typical sizes are 2”, 23/8”, 3”, 4”and 5” cups. The extractor separates fruit into four parts - Pulpy Juice, peel, core (rag, seeds & pulp) and oil emulsion.

The typical operation of squeezer type extractor is shown in fig 5.6. The Head consists of upper and lower cups. The cups has metal fingers that mesh together as the upper cup lowered onto the lower cup. A cutter comes up from centre of the lower cup to cut a hole through the skin in order to allow the inner parts of the orange Fruit flow out. The cutter is part of perforated strainer tube, also sometimes called as prefinisher. Once the strainer tube cuts into the fruit, the upper cup squeezes down into the lower cup. This pressure initially forces the juice burst out of juice vesicles and pass through the perforations of strainer tube. Some of the pieces of ruptured juice sacs ( pulp) also passes through juice. The upper cup continues down word to lower cup maximise the juice extract

Eventually downward pressure causes peel to breakup, disintegrate and pass up through fingers of each cup. Juice flows through strainer tubes into the juice manifold. The core material discharge from bottom of strainer tube through orifice tube. As the peel is forced through the fingers of cups during last stages of extraction cycle, oil is released from the peel. The bits of peel are washed with recycled water to extract the oil from oil sacs. The oil is discharged from extractors as an emulsion with water.

The throughput of a Five Head extractor is vary according to the quality and size of fruit. The Standard operating speed is 100 Rpm or 500 Fruits per Minute. Fruit is not always flows to cup, so 85% utilization is considered to calculate the extractor capacity

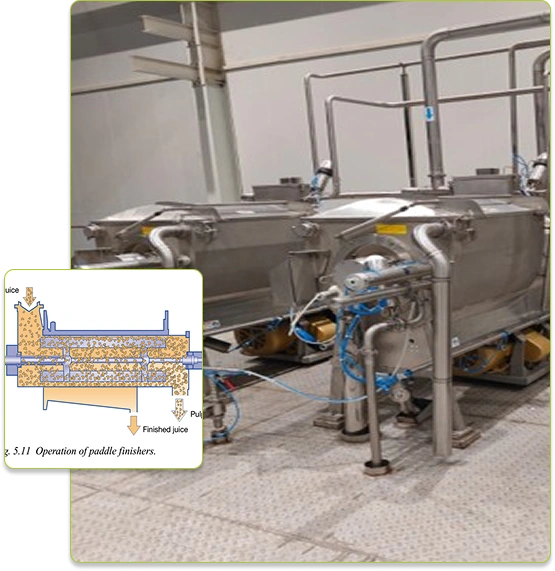

JUICE FINISHERS

After extraction the pulpy juice (about 50% of fruit intake, in Indian varieties about 44-48%) is clarified by primary juice finishers which separate juice from pulp. The finishing process is a mechanical separation method based on sieving.

The juice stream is further clarified by centrifugation. The pulp stream, containing ruptured sacs and segment walls may then go to pulp recovery or pulp washing.

Pulp levels in extracted juice are around 20-25% of floating and sinking pulp. Henceforth pulp is removed from juice with finishers.

These incorporate a set of paddles rotating on a central shaft within the cylinder. The pulp is pushed against the screen by paddles. Paddle finishers apply centrifugal force rather than pressure to separate the pulp from the juice.

Two finishers are often placed in series at the end of extraction line. The upstream primary finisher is not set as tight as the downstream secondary finisher, so it has a higher flow capacity.

CENTRIFUGE- PULP SEPARATOR

Typically the pulp content in juice leaving the secondary finisher is about 12%. This pulp is predominantly sinking (bottom) pulp. If the market requires a juice with lower sinking pulp content, the juice can be further clarified by centrifugal clarification. Also if the juice passing through De acidification and DE bittering unit needs less than 1% pulp to avoid choking of systems.

CENTRIFUGE- OIL SEPARATOR

PEEL OIL RECOVERY: The oil- water emulsion or oil frit, from the extraction process sent to the oil recovery system. Apart from oil and water other fruit substances such as particles of peel and pulp are present. The aim of peel oil recovery system is to separate pure oil from the stream with minimum oil loss

The oil emulsion containing 0.5- 2% oil enters into the first stage of centrifuge (also called De sludger or concentrator). The centrifuge concentrates oil up to 70 -90%. The first stage centrifuge is a three phase machine. The light phase is oil, heavy phase is water and the third phase is residual particulate matter

The concentrated oil phase is then passed through second stage of centrifugation process (or polisher). Within this machine the oil is further concentrated to >99% PURITY.

One tonne of fruits typically yields to 200 -300 Litres of oil emulsion to first stage of centrifuge which intern yield to 3-6 litres of concentrated oil for polisher.

WINTERISATION PROCESS:The polished oil contains some traces of dissolved wax derived from peel of the fruit. At temp. 20 to 30ᵒ C the wax is completely dissolved in oil. To separate wax from oil we need to go for winterisation process. The winterisation process involves precipitating of wax by storing oil at temp. Lower than 1ᵒ C for 30 days, which causes waxes to come out of oil and sediment. The winterised oil is stored in 50 litres drum and stored in cold storage @ -10ᵒ C and is traded as COLD PRESSED OIL (CPO).

De Bittering PLANT

State of the art De-bittering plant from Bucher Unipektin Switzerland is a resin based Filtration plant .

This plant separates Limonene particles from Juice which causes bitterness in Juice. State of the art De-Acidification plant from Bucher Unipektin Switzerland is a resin based Filtration plant .

This is first of its kind plant in India.

This plant reduces acidity in Final Juice and hence provide a flexibility to process Fruits in early season without affecting the quality of final Juice product.

De Acidification PLANT

State of the art De-bittering plant from Bucher Unipektin Switzerland is a resin based Filtration plant .

This plant separates Limonene particles from Juice which causes bitterness in Juice. State of the art De-Acidification plant from Bucher Unipektin Switzerland is a resin based Filtration plant .

This is first of its kind plant in India.

This plant reduces acidity in Final Juice and hence provide a flexibility to process Fruits in early season without affecting the quality of final Juice product.

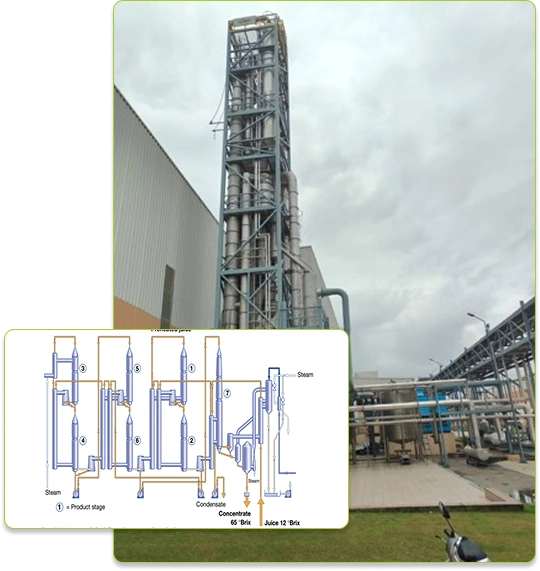

TASTE EVAPORATOR

TUBULAR EVAPORATOR SYSTEMS:The most common Tubular evaporator system used for citrus juice is TASTE EVAPORATOR. It is generally described as a continuous, high temperature short time Evaporator of the long, vertical tube falling film type. The name TASTE is an acronym for THERMALLY ACCELERATED SHORT TIME EVOPRATOR.

The juice is first preheated to 95 -98 ᵒ C. Holding at pasteurisation temperature stabilizes the Juice by means of microbial and enzymatic inactivation. The Product then passes through a number of stages under vacuum until a concentration of products reaches 65 to 66 ᵒ Brix is achieved. By this time the product temperature is fallen to 40ᵒC. The residence time in the evaporator is generally 5-7 minutes or longer.

ESSENCE RECOVERY:During evaporation volatile juice components are stripped from the juice together with the water. These are often recovered from essence recovery system attached to the evaporator. The vapours from early stages of evaporator contain most of the volatiles from the juice. These are captured and sent to still mount on evaporator. The important volatiles are separated from the water by distillation under vacuum and condensed by chilling.

The product essence is a concentrated mixture of aqueous and oil soluble aroma compounds. This essence is separated into oil and Aqueous phases by either decantation or centrifugation. The aqueous phase is called water phase aroma (or essence aroma) and oil phase aroma. The essence aroma and essence oil are sold as separate products to concentrate blenders or Juice Packers and flavour manufacturing companies.

DRUM FILLER

The final concentrated juice of 65+/- 2 Brix is packed in 200 Ltrs MS drum with two 400 GSM and 200 GSM liners inside.

These packed products are stored in Cold storage @-20 Degree Centigrade.

COLD STORE

In-house cold store facility available. Total 4 chambers of each 500 MT storage capacity available.

Cold store temperature is maintained at -20 Degree Centigrade.