Processing Equipment

Our Satisfied Clients

Our clientele includes both domestic & international customers. We are been in this industry for more than 2 years & built a reputation for our competitive prices & consistent quality.

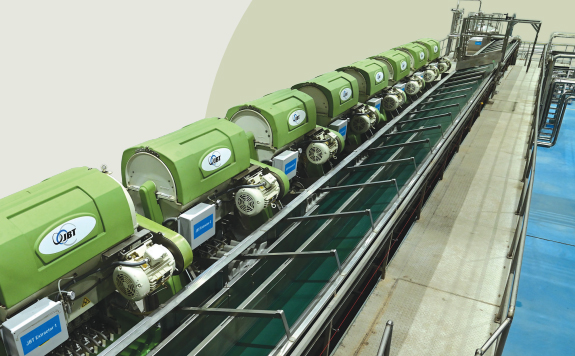

Extractor

Extractor - Squeezer type extractors are place in a row in extractor room. Each extractor is fitted with 5 heads which are available in different sizes so that they can handle different types of available fruits. The typical sizes are 2”, 23/8”, 3”, 4”and 5” cups. The extractor separates fruit into four parts – Pulpy Juice, peel, core (rag, seeds & pulp) and oil emulsion.

Juice finisher Machine

After extraction the pulpy Juice (about 50% of fruit intake, in Indian varieties about 44 – 48 %) is clarified by primary juice finishers which separates juice from Pulp. The finishing process is a mechanical separation method based on sieving. The juice stream is further clarified by centrifugation. The pulp stream, containing ruptured sacs and segment walls may then goes to pulp recovery or pulp washing

Alfa Laval Separator

Typically the pulp content in juice leaving the secondary finisher is about 12%. This pulp is predominantly sinking (bottom) pulp. If the market requires a juice with lower sinking pulp content, the juice can be further clarified by centrifugal clarification. Also if the juice passing through De acidification and DE bittering unit needs less than 1% pulp to avoid choking of systems.

De-Bittering

De-Bittering - State of the art De-bittering plant from Bucher Unipektin Switzerland is a resin based Filtration plant .

This plant separates Limonene particles from Juice which causes bitterness in Juice.

Tubular Evaporator Systems

The most common Tubular evaporator system used for citrus juice is TASTE EVAPORATOR. It is generally described as a continuous, high temperature short time Evaporator of the long, vertical tube falling film type. The name TASTE is an acronym for THERMALLY ACCELERATED SHORT TIME EVOPRATOR.

Filling

The final concentrated Juice of 65+/- 2 Brix is packed in 200 Ltrs MS drum with two 400 GSM and 200 GSM liners inside. These packed Product stored in Cold storage @ -20 Degree Centigrade.

Drum Filler

The final concentrated Juice of 65+/- 2 Brix is packed in 200 Ltrs MS drum with two 400 GSM and 200 GSM liners Inside.

These packed product stored in Cold storage @ -20 degree Centigrade.